The manual color correction setting or RGB replacement and general-use guidelines

The manual color correction setting or RGB replacement and general-use guidelines

Color missing or very light print output exhibited on all colors on pages printed

Color missing or very light print output exhibited on all colors on pages printed

Missing color plane or very light color (one color) on printed pages

Missing color plane or very light color (one color) on printed pages

Solid black pages or horizontal black stripes on pages printed

Solid black pages or horizontal black stripes on pages printed

Repeating horizontal lines appear on pages printed

Repeating horizontal lines appear on pages printed

Non-repeating marks on the front side of page printed

Non-repeating marks on the front side of page printed

Horizontal Lines when Printing from the Lexmark CS310, CS410, CS510, CX310, CX410, and CX510

Horizontal Lines when Printing from the Lexmark CS310, CS410, CS510, CX310, CX410, and CX510

Hieroglyphics, strange symbols or random characters appear on the printed page

Hieroglyphics, strange symbols or random characters appear on the printed page

Streaks, marks, splotches, or clouds near the edges of the printouts

Streaks, marks, splotches, or clouds near the edges of the printouts

Non-repeating marks on the back side of the page check

Non-repeating marks on the back side of the page check

Smearing, smudging, or poor fuse grade on pages printed

Smearing, smudging, or poor fuse grade on pages printed

Envelopes Skewing when Printing from the Multipurpose Feeder on the Lexmark CS310, CS410, CS510, CX310, CX410, and CX510 Printers

Envelopes Skewing when Printing from the Multipurpose Feeder on the Lexmark CS310, CS410, CS510, CX310, CX410, and CX510 Printers

Colors are too dark or black shading is covering partial or entire page

Colors are too dark or black shading is covering partial or entire page

Printer Spits Extra Blank Pages or Prints Random Texts from Ubuntu

Printer Spits Extra Blank Pages or Prints Random Texts from Ubuntu

Lexmark CSx10 / CXx10 Print Quality Diagnosis ? Horizontal Banding on Printed Color Page

Lexmark CSx10 / CXx10 Print Quality Diagnosis ? Horizontal Banding on Printed Color Page

Fixing the "No analog phone line connected to modem, fax is disabled" error message

Fixing the "No analog phone line connected to modem, fax is disabled" error message

Lexmark CS310, CS410, CS510 & CX310, CX410, CX510 ? Diagnosing Print Quality Issues and Warning Messages Related to Imaging Kit

Lexmark CS310, CS410, CS510 & CX310, CX410, CX510 ? Diagnosing Print Quality Issues and Warning Messages Related to Imaging Kit

Repeating dark spots about 30mm intervals check

Repeating Dark Spots About 30mm (1.18 inch) Intervals Seen on Every Printed Pages on the Lexmark CS310, CX317, CS410, CX417, CS510, CX310, CX317, CX410, CX417 and CX510

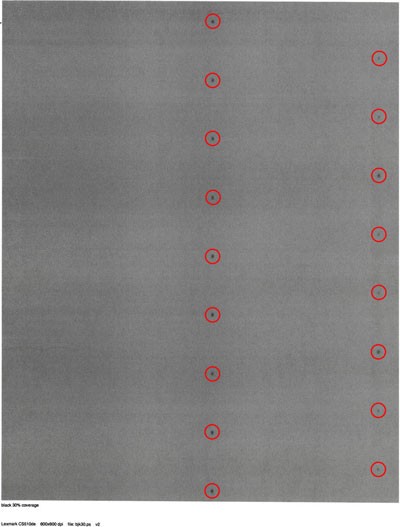

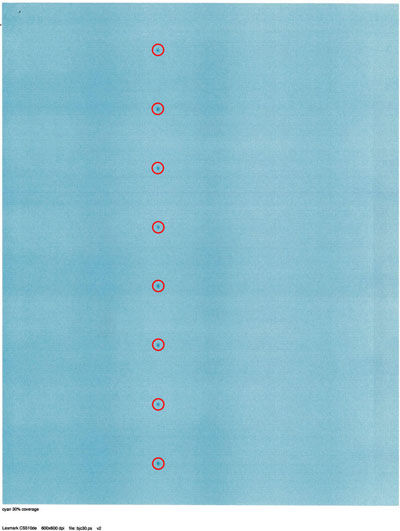

Issue description

Spots of toner are seen on every printed page, repeating at a

30mm

(1.18 inch

) frequency. See sample printouts below.Print defect samples

|  |

This article will help you confirm the problem.

Please refer to the procedures provided below to help determine which hardware part is causing the issue.

Solution

- This defect is most likely due to a damagedCharge Roll.TheCharge Rollis included in thePhotoconductor(PC) Unit.

- To resolve the issue, replace thePC Unit.

LEGACY ID:

SO7573

Service action

This print quality defect is most likely due to a damaged

Charge Roll

. However, be sure to measure the defect interval accurately to determine which hardware part is causing the issue.- Ask the customer to send a sample printout via fax or e‑mail.

- Identify the cause of the issue using thePrint Defects Guidefrom theHelp Menu. To do this, navigate to:Menus button>Help>Print Defects Guide.

- Measure the defect's interval. Refer to the sample printouts in the customer-level section of this document to see how the measurement was done.TheCharge Rollrepeating defect distance is30mm(1.18 inch).

- Check theSupply Levelof thePhotoconductor Unitby printingDevice Statistics. To do this, navigate to:Menu button>Reports>Device Statistics.

- If theSupply levelislow, tell the customer to purchase a replacementPhotoconductor Unitas it may already be worn out.

- If the Supply level is still sufficient, proceed with the next step.

- Check whether the customer has a differentPhotoconductor Unitin order to try swapping it with the original as a test, since if the defect clears when using a differentPhotoconductor Unitthat would prove the original is defective. Should the customernothave a replacement unit to try this test with, however, send a replacementPhotoconductor Unitas the original one might be defective.

- If the defect persists even after replacing thePhotoconductor Unit, escalate the call to your next level of support.

Feedback Submitted! Thank you for providing valuable feedback!